With Grafana as part of its IoT monitoring solution, AgriTech helped industrial hemp farmers increase production 4x

In 2019, Alexander Mann was working in the microchip industry, putting in 12-hour shifts that took him away from one of his favorite pastimes, gardening. Mann has roots in rural Virginia, where he grew up in Fauquier county surrounded by thousands of acres of farmland. At the time, he devoted a lot of attention to growing 14 varieties of tomatoes, squash, cucumbers, zucchini, beans, peas, spinach, and sunflowers. (He’d sell the tomatoes and spinach to a local restaurant and share the leftovers with friends and family.) But his grueling work schedule made it hard. “I quickly learned that I did not have enough time to tend to my garden,” he recalls. “I started looking for ways that I could remotely water or check on my plants.”

At the time, the products on the market that could help him were either too costly for a hobby gardener or required special internet connections that weren’t available by his rural farmhouse just outside of Marshall, Va. “It just wasn’t feasible,” he says. And then a seed was planted: What if Mann could learn about IoT and create his own setup?

He determined that the key was to use cost-effective sensors and electrically-controlled valves featuring solenoids (a type of electric coil often used to power a switch); he would then connect them to a local network without an internet connection. Within a year, he had his own “garden bot” with a multitude of environmental sensors, which allowed him to care for his garden even when he wasn’t there. He even added a drone for additional remote monitoring.

Mann’s personal project quickly grew into AgriTech, his Virginia-based agricultural tech consulting company where he is the CEO. The company uses sensor data analytics, AI, IoT, and Grafana to help farmers improve their crop health, maximize their yield (and resulting profits), cut costs, and offset their CO2 emissions. In other words, he’s setting out to revolutionize the farming industry.

Unearthing potential in industrial hemp

Mann’s first target? Industrial hemp farming thanks to his partnership with Pure Shenandoah, one of the largest industrial hemp fiber growers in Virginia.

Unlike the more well-known flowering plants used to cultivate cannabis, industrial hemp is a long, tall, stalky plant that grows like bamboo and is not for human consumption. But it has plenty of benefits. Raw hemp fiber can be manufactured on a commercial scale to create building materials (your home could be made from hemp-crete!) and for common goods such as insulation (industrial hemp is more fire-resistant than fiberglass), animal bedding, woven fabric, toilet paper, paper towels, and tissues. Fun fact: During World War II, the U.S. government launched a “Hemp for Victory” campaign to encourage farmers to grow hemp that could be used to make rope for the Navy. Industrial hemp can even be used to make sound barriers along highways—or in the case of Pure Shenandoah, you can add design elements to your first storefront in Elkton, Va., with the material just for good measure.

The versatility of industrial hemp fiber isn’t its only selling point. “Farmers are paid per bale that they grow, and industrial hemp has tons of potential to be a cash crop and a viable industry for farmers moving forward,” Mann says.

But, Mann points out that industrial hemp had been outlawed for so long that the best practices for optimal growing have been lost. “That is where Grafana comes in, utilizing the data to reclaim the lost knowledge and continue building our understanding of this amazing industrial crop,” he says.

Case in point: In 2020, Pure Shenandoah grew 15 acres as a pilot project, which yielded about four tonnes (roughly 8,800 pounds) in total. When Pure Shenandoah partnered with AgriTech in 2021, they scaled to grow a little more than 500 acres of industrial hemp, which yielded 750,000 pounds of fiber. This year, Pure Shenandoah is on track to plant more than 800 acres of industrial hemp fiber across more than 20 partner farms in Virginia. Each farm will have a Grafana instance running locally or in the cloud to stream data directly from the farms into dashboards built and managed by AgriTech.

“The systems [Alex] put in place propelled us to having the best results we have had in our three years of cultivation in Virginia,” says Pure Shenandoah Cultivation Director Jacob Johnson.

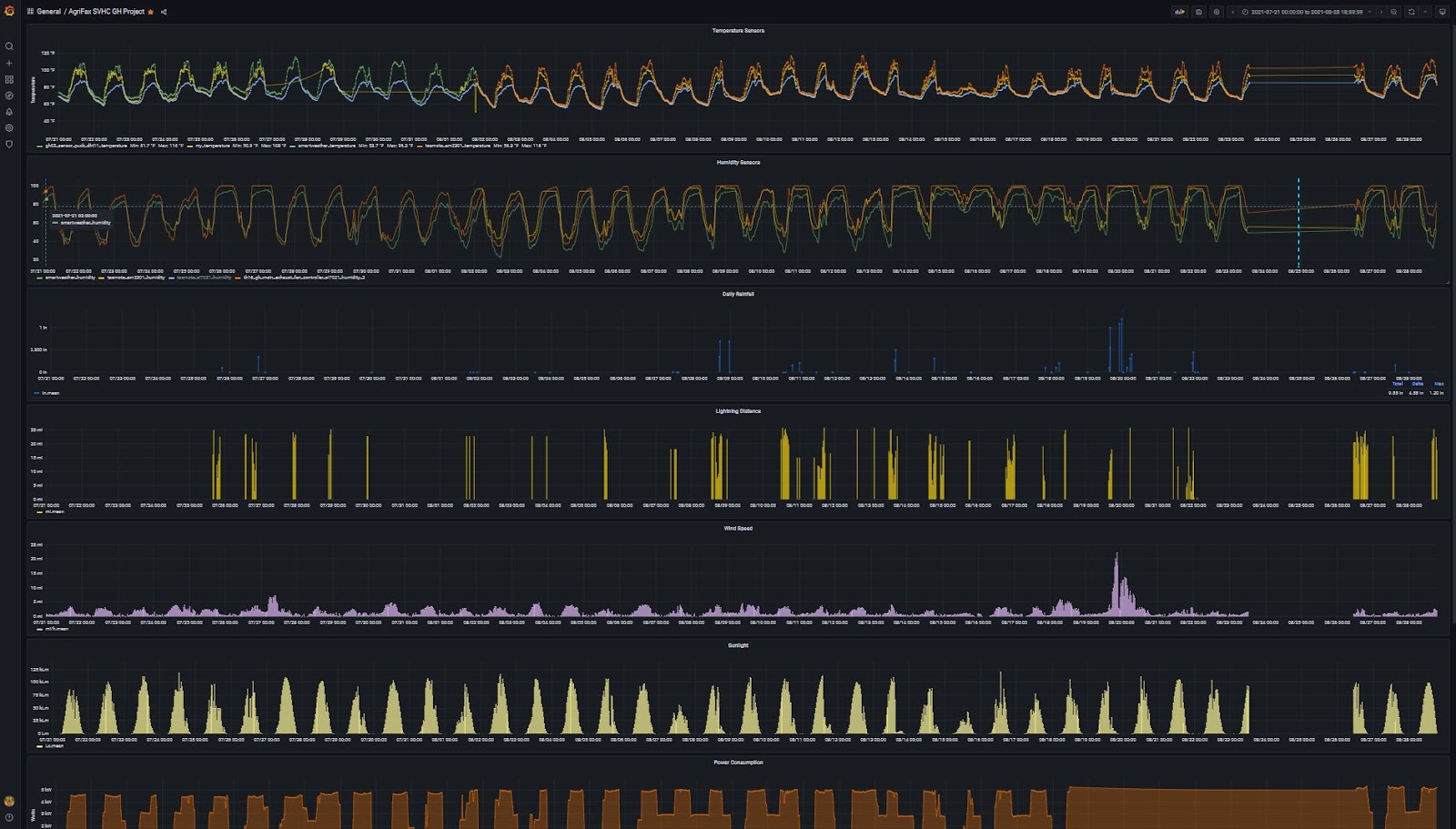

A snapshot of 90 days worth of data points coming in from one of Pure Shenandoah’s greenhouses showing (from the top) multiple temperature and humidity sensors, rain, lightning, wind speed, luminosity, and energy consumption.

Seeds of development

When Mann first began his personal garden monitoring project, he was using Node Red to build simple dashboards to observe the data and metrics. “I had a good database — it was clean and the data points were tagged well and organized, but I didn’t really like the way that my database was represented on a dashboard. It felt very rudimentary and almost blocky,” he says.

A quick Google search for other options turned up images of Grafana dashboards. “I saw these really beautiful, robust, complex dashboards, and I thought, ‘This looks so cool. This is what I want’,” he says. “I’m a very visual learner, so looking at a spreadsheet of data just gives me a headache.”

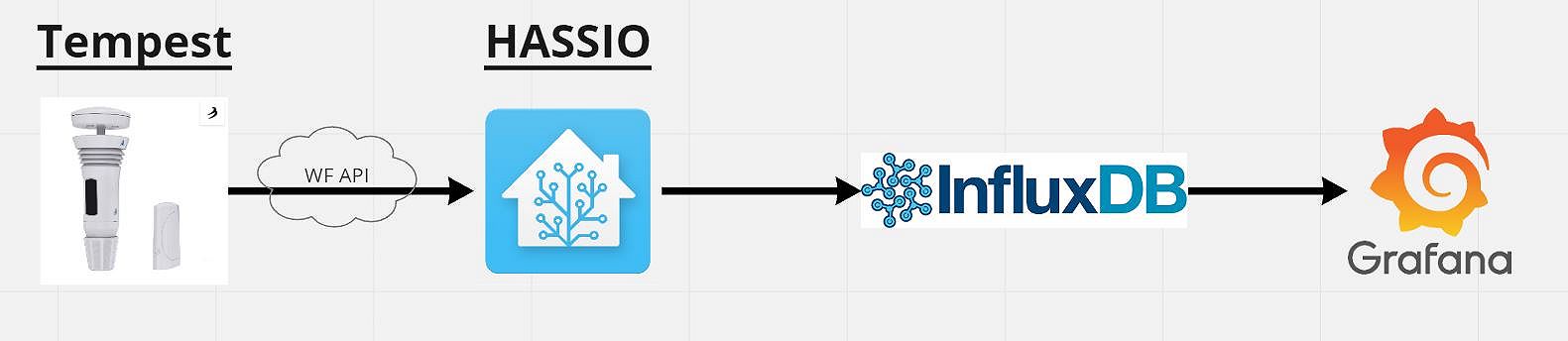

Using a Raspberry Pi and the Python-based Home Assistant OS, he began utilizing the Grafana add-on on his Raspberry Pi server as a local container. Mann then set up a Tempest weather station to monitor the temperature and other data. “I was able to use Tempest’s API to feed the data from the weather station directly into InfluxDB,” he says. “From there, it goes directly into Grafana for the visualization and the dashboards, which is pretty exciting.”

When he decided to launch AgriTech, Mann started spending his weekends traveling around Virginia’s Fauquier County and meeting local farmers. “I would do drone scans for free, generate multi-spectral reports, and help educate them on this new tool that could be utilized to help their operations,” he says.

Edge computing was as important to AgriTech’s beginnings as it is to its future. Drones allow the company to account for the individual heads of plants that emerge from seed and calculate biomass and measure chlorophyll density (key to calculating carbon sequestration), and Mann is expanding AgriTech’s offerings by deploying Arable, a more advanced outdoor field monitoring station, for this season’s crops.

AgriTech’s flagship UAV posing in front of a large industrial hemp field. Utilizing the SlantRange 4p Multispectral Sensor, the company is able to measure and quantify many variables in a farming operation before they become visible to the human eye.

Ideally, Mann aims to have about 70 data points coming in every 60 seconds, and they will dig into details ranging from the soil (pH, electrical conductivity, nitrogen-levels, temperature, moisture content, and more) to the sunlight (UV exposure, solar radiation, etc.).

“I’m looking at every environmental input that I can quantify,” he says.

Harvesting results

Before working with AgriTech, operations across Pure Shenandoah’s farms were manual and time consuming.

The management system that Mann set up for Pure Shenandoah includes a customized app that features several Grafana dashboards, which centralize information for faster and better decision-making. “Once it’s built out, my client can log in and the data is right there in front of them, which is really cool,” he says. “They would check all these dashboards in the morning to give them a better idea of what was going on out in the greenhouses and how to respond.”

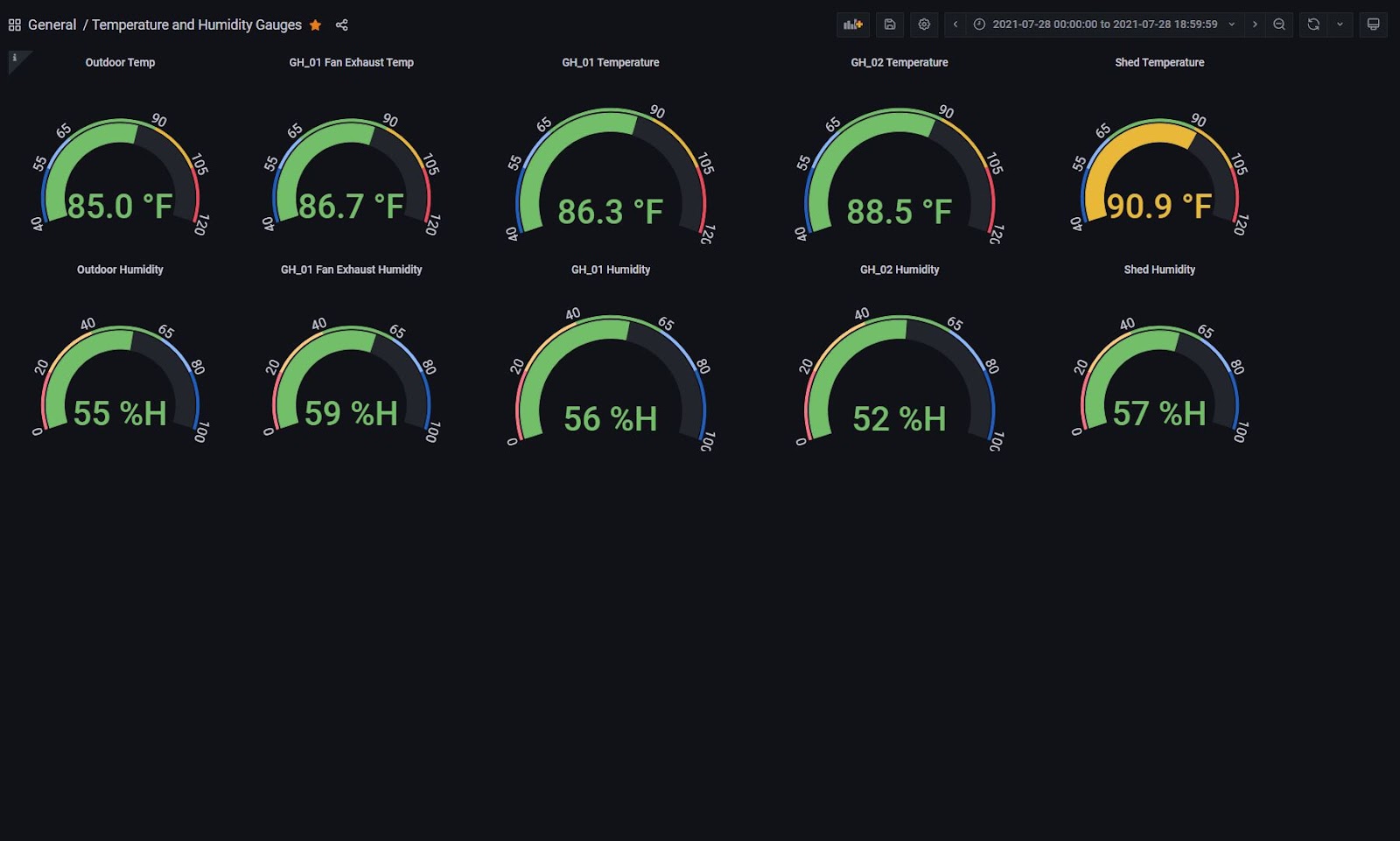

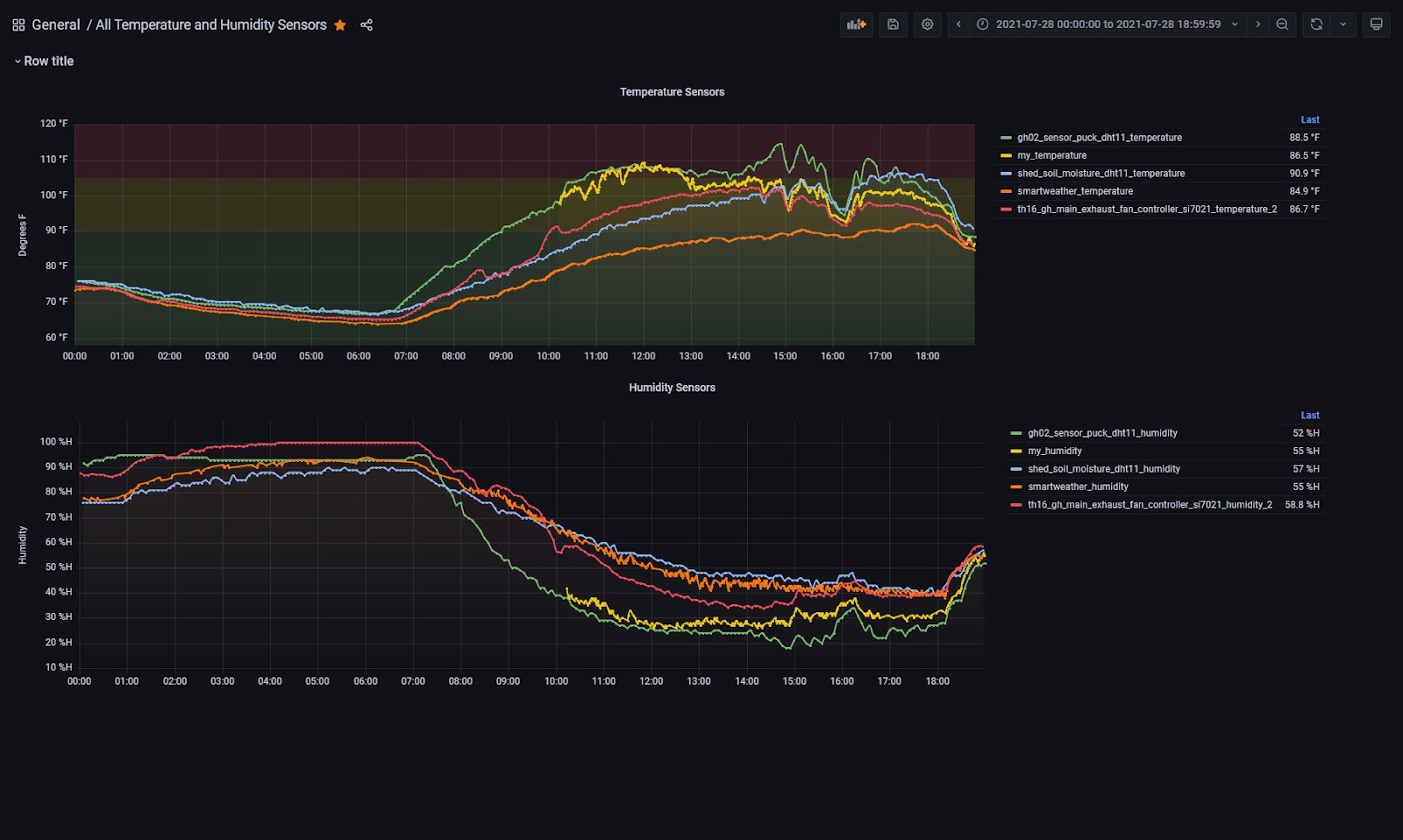

A custom Grafana dashboard showing all temperature readings on the top gauges and all humidity readings on the bottom gauges. Mann explains, “With this, the client can see not only what is going on in grow areas, but also compare it to environmental conditions in other zones, giving a more comprehensive picture of what is going on in their operation”

For example, visualizing the rising temperature and rapidly falling humidity in a greenhouse in real time can have an instant impact. A farmer could easily tell that the plants needed water at, say, 10 a.m. to offset the evaporation that’s going on in the greenhouse. “That’s a novel thing that a simple spreadsheet wouldn’t be able to tell you, but with Grafana we can see it right in front of us as soon as the data comes in,” Mann says.

And if a problem occurs, the Pure Shenandoah team can now detect it immediately, before any real damage is done. If a circuit breaker trips and the greenhouse fans lose power, it could have devastating effects for the plants. With Grafana, Mann explains, “I was able to set up alerts using if/then statements: If the power drops below this many watts, then send an alert.” He adds, “It actually did save us a couple times. That extra set of eyes and ears looking out for us was like an insurance policy.”

With less time and fewer resources dedicated to manually monitoring and troubleshooting issues around their farms, Pure Shenandoah’s Johnson says, “this gave us the chance to really start to understand operating expenses.”

The company was able to introduce automation into their electrical and irrigation operations in 2021, which allows growers to manage their crops remotely and collect more data on power, water, and other important variables.

Before Alex, we only had manual on/offs for all the electrical and irrigation. Now, I’m able to check and interact with the app he configured to take care of the plants remotely without even leaving my house. Using Grafana’s dashboards to visualize our usage metrics, I’m able to make real-time decisions with confidence.

Jacob Johnson, Cultivation Director, Pure Shenandoah

Pure Shenandoah was especially keen on analyzing and optimizing their energy use, so Mann built a Grafana dashboard (below) to help calculate and track the organization’s daily energy footprint and overall power consumption in real time.

Mann was even able to unearth targeted ways Pure Shenandoah could be more energy efficient. The dashboard below shows all of the temperature and humidity sensors across Pure Shenandoah’s farms. “During the peak of the summer, we had about five different ones — some inside, some outside, some in different zones. Being able to see how the temperature changed at different times of day or under different conditions really allowed us to calibrate and save energy,” Mann explains. “We found that we could set automation rules for the main ventilation fans to turn on when the temperature got above 90 degrees and off when it fell below 80 degrees.”

Although it’s still too early to quantify the exact savings, Johnson notes, “I can assure you we saved a good chunk of money on utilities and labor. We are looking forward to continually adding more automation throughout the years.”

Sowing the future

Since industrial hemp is a new crop for today’s farmers, there are a lot of unknowns about how to grow it. As part of AgriTech’s work, the company is doing research trials in collaboration with Pure Shenandoah. Mann set up a controlled environment in a greenhouse that is fully automated for optimal craft hemp production.

“We’re growing different strains of the commercial fiber variant and trying to identify different strains or genomes. We want to selectively breed the ones that are better suited for this environment,” Mann says.

With data tracking, AgriTech can validate what went into the crop and measure the inputs and the outputs, which can lead to better results over time. Grafana plays a significant role in that. “Being able to utilize a dashboard really helps because we can fine-tune the environment, subject the plants to certain conditions, and then see how they respond.” As a result, they can figure out ways to improve the process over time. With that information, Mann hopes to come up with an encyclopedia or “recipe card” for how to grow hemp fiber.

“The ideas and systems that Alex installed made the intense process of cultivating high-quality hemp at scale a lot less stressful,” says Johnson.

Grafana also plays an important, two-pronged role in AgriTech’s services. “My goal with Grafana is to visually represent data flowing through our network and be able to gain innovative insights on our carbon footprint in real time,” he says.

One important characteristic of hemp, in fact, is its limited impact on the environment. “It can store carbon dioxide for long amounts of time,” which makes it better for the environment than traditional crops. Its high degree of permanence gives it more value in the carbon credit market. And the more credits a farmer can earn, the more income they can generate.

Using Grafana helps tremendously when it comes to AgriTech’s partner farmers getting those credits. “Being able to have a dashboard for our third-party carbon credit validators helps them verify and audit our operation,” Mann explains.

Reaping the benefits

Conventional farming methodologies and techniques are “somewhat inefficient,” Mann notes, and they tend to require large inputs of external fertilizer, external herbicides, and pesticides. He doesn’t think that’s necessary. “If we have innovative and novel technologies deployed on these operations, we can really gain an intimate understanding of what’s going on out in the field and be able to make better operational decisions to get better over time and make it sustainable.”

“Alex’s hard work is matched with a sustainable lens that is very important for the future of farming,” says Johnson.

“I put in my two weeks notice at my well-paying job to pursue this dream,” says Mann. “There’s a lot of potential for creating jobs, helping farmers, and enriching communities … and I really want to do everything I can to teach people about the benefits of industrial hemp and how technology can be utilized for good in the agricultural space.”