Note: By registering, you agree to be emailed information about this event recording and related product-level information.

Products

Core LGTM Stack

extend observability

end-to-end solutions

Open Source

Community resources

Dashboard templates

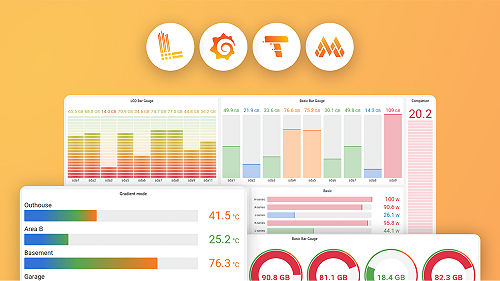

Try out and share prebuilt visualizations

Prometheus exporters

Get your metrics into Prometheus quickly

end-to-end solutions

Opinionated solutions that help you get there easier and faster

monitor infrastructure

Out-of-the-box KPIs, dashboards, and alerts for observability

visualize any data

Instantly connect all your data sources to Grafana

Learn

Stay up to date

Technical learning

Docs

Get started

Get started with Grafana

Build your first dashboard

Get started with Grafana Cloud

What's new / Release notes

Company

Help build the future of open source observability software Open positions

Check out the open source projects we support Downloads

Free forever plan

(Surprise: it’s actually useful)

- Grafana, of course

- 14 day retention

- 10k series Prometheus metrics

- 500 VUh k6 testing

- 50 GB logs, traces, and profiles

- 50k frontend sessions

- 2232 app o11y host hours

- and more cool stuff

No credit card needed, ever.

end-to-end solutions

Opinionated solutions that help you get there easier and faster

visualize any data

Instantly connect all your data sources to Grafana

Grot cannot remember your choice unless you click the consent notice at the bottom.